All Over Screen Printing Methods

Approaching the task of imprinting on apparel and fabrics provides several options, each with unique benefits. The simplest and most effective approach is Printing Using Different Printing Methods, but conventional clothing manufacturers have to consider limitations.

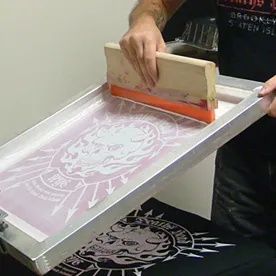

X Athletic Wear offers an exceptional solution through our Cut And Sew services. Instead of Printing directly on pre-made garments, we surpass the constraints faced by other manufacturers by providing cut panels for Printing. Whether you face Sublimation’s white blemishes or require all-over Screen Printing, we have you covered. Our expertise extends to placing logos on sleeve edges or Printing on unconventional areas. If you need a distinct pattern on your hoodie pocket while maintaining a different overall look, we can handle it. Count on X Athletic Wear to find practical solutions for any print positioning challenge, ensuring customization is never limited. Our printing options include silk Screen Printing, all-over Sublimation printing, Heat Transfer Printing, Digital Printing, and even Direct To Garment Printing.